The Importance of Proper Fire Code ASME Testing

By Richard Price / Published April 2023

When the power went out at a large condominium complex, the emergency generator failed to operate, incapacitating the emergency lights, fire alarms, intercoms, security, elevators, air conditioning, and water and life safety equipment. Poor electrical connections and controls prevented the emergency generator from distributing the power. These electrical connections also arced, causing a fire that produced heavy smoke and briefly triggered the fire alarm. This left handicapped residents on oxygen and other life support equipment panicked and endangered. Other residents trying to evacuate in the dark were subject to tripping, falls, and general panic. In addition, emergency medical services (EMS) personnel could not immediately evacuate the large number of elderly people who needed help.

The deficiencies that led to this scenario would not be revealed by standard testing, but proper fire code ASME testing, as per State of Florida 2008 fire code law, would uncover them.

Testing

The five key areas for ASME V testing to update certification data are as follows:

- Structural base (concrete consolidation)

- Roof (membrane)

- Electrical systems (2008 State of Florida fire code)

- Balconies (concrete consolidation)

- Mechanical systems (2008 State of Florida fire code)

The scope of building maintenance testing has been challenging to owners and property managers. Each property design has different challenges and multiple owner points of view to be satisfied while still meeting the requirements for building and fire code safety.

All buildings have key components that were certified to jurisdictional building codes and fire codes, so as to be serviced and maintained for safety-first performance reliability.

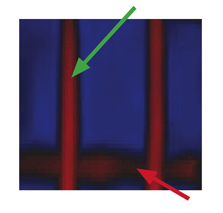

Visible and acoustic inspections are the critical first stage to be carried out for a safety-first facility. In the past, equipment data was only acquired with meters and visual and acoustic data. Rod tapping/impact on the surface is subject to personal interpretation of the sound with restricted depth ability and density limitations. Data from any area that is unsatisfactory is typically given to the engineers to solve and or improve.

BUILDING & STRUCTURAL ENVELOPE ASME V SUBSURFACE RELIABILITY TESTING

ASME V NON-DESTRUCTIVE EXAMINATION RELIABILITY SUBSURFACE IMAGING, ASTM

Florida 2008 Annual Fire Code Reliability Testing,

This is typically inspected by the State Fire Marshal(s).

Concrete Area: Unsatisfactory

Steel: Unsatisfactory

Is the Data Current?

The following are the key areas that must be examined for the 40-year certification data as per ASTM.

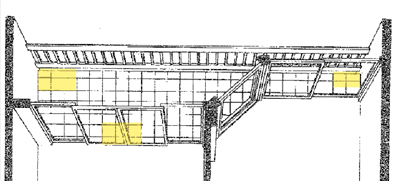

Structural Base—concrete consolidation and steel density in floor, walls, and columns. ASME V image concrete accessible perimeter of building and interior concrete-base floor areas for uniform consolidation and density as per ASTM.

Roof—concrete consolidation and rebar density and membrane and perimeter seal inspections should be done every five years. ASME V Infrared image accessible roof seal, drain areas, lightning protection, electric panels and membrane, including the concrete deck below, should be part of the annual inspection.

Electrical System—fire code, generators(s), arc flash, alarms, and electric termination.

The annual fire code testing as per the 2008 State of Florida law requires a fire code inspection and infrared image subsurface electrical testing with electrical inventory bound in a sealed annual report and kept where management can provide it as needed.

All electrical-damaged areas such as deficient termination, electrical arc-damage areas, or power surge lightning-marked (maybe lightning-struck?) equipment should be repaired as per an electrical engineer.

Balconies—concrete and steel, doorways (both sides), and the current density and columns must be checked for current density and strength requirements.

The ASME V image accessible shows area of balconies, glass intersections, and sliding glass door intersections, including inside unit base floor areas, to reveal uniform concrete consolidation and density. All damaged areas that are marked should be repaired as per the engineer’s specifications.

Mechanical Systems—HVAC, waste, plumbing, electrical inventory, and the fire code.

Annual fire code testing must be carried out as per the 2008 State of Florida law. Fire code inspection and infrared image subsurface electrical testing are for all accessible terminations.

Using Annual Reports ASME V Historical Materials Data as per State Law

With inspections and documented testing as per jurisdictional codes, including as per National Fire Code and ASTM, the situations initially described probably could have been minimized or avoided. Even if the equipment had failed, management would have certified documented reports to prove that reasonable precautions had been taken to avoid the failure, thereby mitigating investigations and extra expenses that could ensue.

Richard Price

Predictive Image Energy Testing (PIET)

Richard Price holds his ASME National Board Commission No. 11628 & State Fire Marshal FL-292, USA & Global, and Certified Non-Destructive Examination Level I, II, III No. 4188, USA & Global. Predictive Image Energy Testing (PIET) can be reached at 305-301-9663, by email at AsmePiet@outlook.com, or visit www.piettesting.com.